On September 29, 2023, EPA published a draft guidance and corresponding test method to allow the addition of planktonic Legionella pneumophila claims for cooling tower water.

These documents have been released for public comment only and are not yet able to be used to support claims. EPA is accepting comments on the docket for 60 days (due 12/01/23) which may result in future changes to the guidance and the test method. CBC’s Legionella work group was very involved in the development of this test method and also provided input to EPA on the guidance document.

SRC Senior Efficacy Consultant, Denise Fernandez, has reviewed the guidance and provided a high-level summary of the guidance document/test method requirements:

What is Planktonic Legionella pneumophila?

Legionella pneumophila is the bacterium that causes Legionnaires’ disease and Pontiac Fever. Planktonic bacteria are bacteria that drift, float, or swim weakly in a body of water.

This bacterium grows naturally in freshwater systems but can quickly lead to an outbreak when it infiltrates cooling tower water systems. Contaminated cooling tower water can aerosolize droplets of water containing Legionella pneumophila and push them out into a building. An occupant who breathes in a contaminated water droplet is at risk of catching Legionnaires’ disease or Pontiac Fever. Proper maintenance of cooling towers is particularly important, as they are used to cool large buildings, generally with many occupants, which leads to a risk of exposing large numbers of people.

In response to this concern, EPA and the CBC Legionella work group have been working diligently to develop a draft guidance and test method for testing products and registering claims against planktonic Legionella pneumophila in cooling tower water systems.

Product Efficacy Testing for Legionella Claims in Cooling Tower Water

The current guidance and test method are only applicable to soluble liquid and solid concentrate formulations. EPA requests that you contact them (prior to testing) for discussion of other product types. In addition, this guidance only addresses claims for reducing planktonic L. pneumophila in cooling tower water. Approved claims will not include sessile or adherent bacteria. This testing does not support Legionella biofilm claims or claims for Legionella inside of protozoa (amoebae) in cooling tower water.

Test Method

The required test method is MB-42: Method for Testing Antimicrobial products against Legionella pneumophila in Simulated Cooling Tower Water (LSCTW). This method is based on the AOAC 960.09 Germicidal and Detergent Sanitizing Action of Disinfectants test (currently used to support food contact sanitizer claims for non-halide antimicrobials) with modifications incorporated from the European Legionella quantitative suspension test EN 13623.

What primarily sets this new test method apart from the standard AOAC 960.09 test method is increased replication (3 flasks per batch) and the inclusion of interferences in the testing. The inclusion of interferences is intended to simulate variations in water quality parameters and cooling tower system materials and design, both of which can impact a product’s efficacy.

Testing Parameters

Testing must be conducted using Legionella pneumophila subspecies pneumophila ATCC 33152 with 3 batches formulated at the lower certified limit (LCL). Three flasks per batch, plus a control and sterility flask, must be assayed on each test date. Testing of each batch must be performed on separate days using separate cultures. For concentrate products, the diluent must be either 375 ppm OECD hard water, 400 ppm AOAC synthetic hard water, or ≥200 ppm tap water.

Testing must be conducted at 30±1°C. The neutralization control procedure (Appendix 5 of MB-42) consists of three parts and is very similar to how the neutralization control is performed in AOAC 960.09.

Contact Time

The guidance does not specify a contact time and whether there are any limitations. EPA included a contact time in the sample use direction language provided in the guidance, so for now we believe contact time will be required on the product label.

Performance Criteria

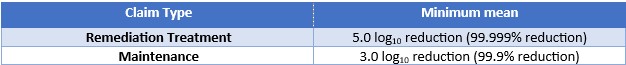

Performance criteria are provided separately for remediation claims/plans versus routine maintenance claims/plans. Remediation plans are short-term actions that bring the system water quality, such as bacterial levels, to acceptable levels as defined in the water management plan and/or applicable federal/state/local regulations. Routine maintenance plans are part of the water management plan that addresses the day-to-day operations of a cooling tower system to maintain the system. The performance criteria for remediation vs. maintenance claims are as follows for each independent test date:

All testing must be conducted in compliance with Good Laboratory Practices (40 CFR Part 160).

Labeling

The Draft Guidance Appendix also contains example marketing claims, and required label contents and language for products intended for routine maintenance and/or remediation claims.

The SRC Efficacy Team continues to monitor the draft guidance and work with applicable trade associations to provide comments to EPA. Please contact your SRC consultant for questions on testing products with the proposed method.

Denise Fernandez

Senior Efficacy Consultant

Published October 3, 2023